How to setting time for one head gear pump mineral oil filling machinery

Controled by micro-computer, fill liquid by setting the filling time and speed.

Filling Liquid From 3-3000ml very precisely.

Digital Panel, very easy to operate.

Technical

Parameter of semi automatic lotion liquid filling machine:

Voltage: AC 180V-260V (pls leave

a message if u need 110v machine )

Power: 30W

Filling Range: 3ml-3000ml

Max Flow Rate: 3.2L/min

Package Size: 280X250X160

(mm)

Weight: 5kgs

Max Suck Distance: 2meter

Anti-dripping Funtion:

Available

Memory Function out of power:

Available

Interior diameter of filling

nozzle: 5mm

Lotion

Gear Pump Digital Filler Characteristics:

1. Import single-chip

microcomputer control, high efficiency, low power consumption

2. Automatic counting function,

effectively control filling quantiy

3. LCD display, touch screen is

very easy to operate

4. High filing accuracy

5. Wide Voltage range

6. Working performance is stable

and can be used for long time

7. This can self-suck the

liquid.

8. The pump can stand acid and

alkali

9. Anti-dripping design.

10. Reasonable design, made of

stainless steel, meet GMP requirement

semi automatic lotion liquid filling machine panel function:

Filling time : for adjusting the filling time

Filling time : for adjusting the filling time

Waiting time : waiting time between each filling when the

machine is filling automatically .

Counter : filling counter

Filling speed : adjusting the speed

Fiilling machine controller

: for adjusting the filling range .

When you turn on the machine , push the button "setting" When the filling range

reaches what you want , push the button "setting" once again .The machine will

keep the filling range in memory .

Operation

instruction:

1, turn on the machine ,and put the bottle under the

filling head

2, push the button "setting". When the filling

reaches the range you want , push the button "setting" once again . Then the

machine will keep the filling range in memory .

3, push the button "auto ", and it will work

automatically . Push the button "manual", and it will work manually .

4, the warranty of the machine is 1 year .

The pump is diaphragm pump and is consumable . When

you find the filling turns slow, please change the pump .

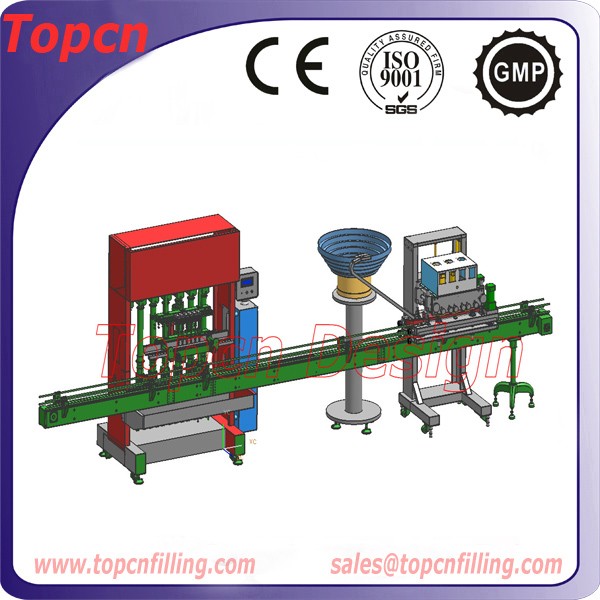

Our digital pump filling machine has 1 head, 2

heads,3head,4head and

6heads:

2

nozzles pump digital filler

Three

head gear pump filler

Four

head Lotion Gear Pump Digital Filler

Six

head digital filler

Packaging

& Delivery

1, Packaging Detail: standard export wooden case package or carton.

2, Leading time: 1-3 days

3, Delivery time: depend on ways of shipping

Shipping & payment

1,ways of shipping:

1) Small machine will shipped by express (DHL, EMS, FedEx and so on) or air

2) Big order and big machine shipped by sea (FOB Shenzhen/CIF)

2, payment methods

We

accept LC, TT, West Union , Papal or MoneyGram 1, Packaging Detail: standard export wooden case package or carton.

2, Leading time: 1-3 days

3, Delivery time: depend on ways of shipping

Shipping & payment

1,ways of shipping:

1) Small machine will shipped by express (DHL, EMS, FedEx and so on) or air

2) Big order and big machine shipped by sea (FOB Shenzhen/CIF)

2, payment methods