2016-10-10

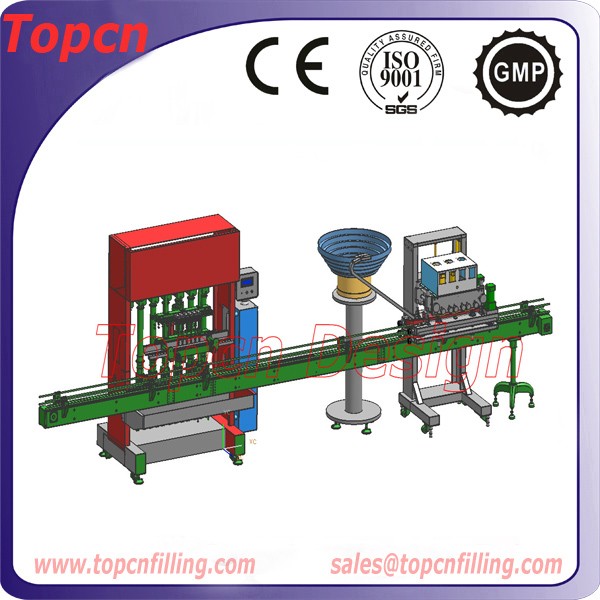

6 heads linear filling machine honey bottles inline screw capping machinery máquina de llenado miel

6 heads linear filling machine honey bottles inline screw capping machinery máquina de llenado miel is specially made for all kinds of viscosity materials, such as jam, chocolate paste,peanut butter, honey, butter, Mayonnaise, ketchup etc. And all kinds of jam with small fruit pieces filling in bottles . By adjusting the position pump, it can fill all of the bottles in one filling machine, with quick speed and high precision.Use automatic piston pump executive filling.

Main technical parameters of 6 heads linear filling machine honey bottles inline screw capping machinery máquina de llenado miel

HS code----8422303090

Output power2000W

VoltageAC220V/380,50/60HZ

Machine weight ------800kg

Productive Capacity----- 20-80BPM(customized)

Machine size----1300*900*1550mm

Filling Range-----100-1000ml (Customer made available)

Control Style------PLC control

Time adjust--------electronic adjust

Packaging------------wooden case packaging

FEATURES

1.Fully in accordance with the ISO standard production and passed CE certification

2.It is easy cleaning and disinfection by the unique design

3.It is applicable for various viscosity liquid ,high precision.

4.We can add or decrease the filling speed according to your needing

5.Customers can determine the number of filling and filling heads by customer's demand

6.The parts which contact material are SUS316L stainless steel and others are SUS304 stainless steel

7.PLC control system, color touch screen display, control motor speed automatically

Filling for honey, sauce paste, oil, detergent shampoo,hand washing,wave liquid,syrup

Our filling machine is suitable filling honey, sauce paste, cooking oil,essential oil, detergent shampoo,hand washing,lubricating oil,wave liquid,syrup, water etc.

Technology parameters:

Filling capacity

25-250ml,50-500ml,150-1000ml,500-2500ml(different specifications can choose to order)

Filling speed:50-80 bottle / min (refers to the 50-500ml range of 6 calculations)

Filling accuracy<±1%

Power Supply:380V 50HZ

Pressure(MPa):0.5-0.7

Outline dimension(mm):2000*870*1900

Weight(kg):500

This Filler is manufactured with heavy duty 304 stainless steel, high quality tig-welded tube frame and is available with 1 to 16 Fill Heads. It also comes standard with PLC controls and color touch screen HMI, a stainless steel reservoir, and Pneumatic Indexing Gates, plus many more features. Further options are available for even more versatility. Overflow Fillers are commonly used for filling beverages and other thin products, especially where foam or bottle inconsistency might be an issue.

Applications of liquid detergent filling machine

Our fillers are most commonly applicable for pharmaceutics, daily chemicals, foodstuffs, cosmetics, pesticides and other industrials;

Typical application: used for filling liquidity is good material, such as filling liquid and paste material, such as water, oil, juice, detergent, sauce, salad, butter, margarine, ketchup, jam, cream, honey, shampoo etc.

Suitable for various packing such as bottle, jar, can, cup, bag, barrels, etc;

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us

automatic edible oil filling capping machine автоматическое заполнение укупорочные машины

This automatic edible oil filling capping machine автоматическое заполнение укупорочные машины used for filling edible oil such as vegetable oil, salad oil, olive oil and so on.

Automatic controlled by computer PLC, touch screen control panels. Totally enclose form,submergence filling , high measurement accuracy. Compact and perfect feature , liquid cylinder and conduits easy dismount and clean.

It also may suited various figure containers.

The machine is used high-quality stainless steel frames, international famous brand electrical components, also applied to GMP standard requirement.

Details about automatic edible oil filling capping machine автоматическое заполнение укупорочные машины

1, This Automatic Healthy Cooking Oil Filling Machine has compact structure, flawless control system, and is convenient to operate with high grade automatism.

2,All the parts contacting the media are made of high quality stainless steel, able to bear corrosion and easily rinsed

3,Adopts high precision and high speed ration filling valve so that the oil level is exact with loss, ensuring high quality filling.

4,The capping head has constant twisting movement, which ensures capping quality, without damaging caps

5,Adopts high efficiency cap tidying system, with flawless equipment for feeding caps and protecting

6, Needs only to change the pinwheel, bottle entering screw and arched board when changing bottle models, with simple and convenient operation.

7,There is flawless equipment for overload protecting, which can protect effectively machine and operator safety

8,This oil filling and capping machine adopts an electromotive with transducer adjusting speed, and is convenient to adjust productivity.

9,All the main electric elements, transducer, photoelectric switch, near switch, and electric controlling valve are imported to ensure the high quality performance of the whole machine.

10,The control system has functions for auto controlling of oil levels, checking and alarming for cap shortage, and team output counting.

11,All pneumatic components elements are Famous brand-edible oil filler- oil filler -salad oil filler

Current supply : 220V or 380V-50HZ or according to client voltage requirement

Filling nozzle: 6

Power : 1.5KW

Production Capacity : 3500-4000 BPH

Error Range: 1%

Filling volume range : 1L-5L

Pneumatic air-operated source: 0.6Mpa clean and Stably compressed air -- 0.5M3/min

Machine Weight : 630kg

Machine Dimension : 2000mm x 1000mm x 2400mm

2016-10-07

semi automatic lotion liquid filling machine digital gear pump mineral oil filling machinery

How to setting time for one head gear pump mineral oil filling machinery

Controled by micro-computer, fill liquid by setting the filling time and speed.

Filling Liquid From 3-3000ml very precisely.

Digital Panel, very easy to operate.

Technical

Parameter of semi automatic lotion liquid filling machine:

Voltage: AC 180V-260V (pls leave

a message if u need 110v machine )

Power: 30W

Filling Range: 3ml-3000ml

Max Flow Rate: 3.2L/min

Package Size: 280X250X160

(mm)

Weight: 5kgs

Max Suck Distance: 2meter

Anti-dripping Funtion:

Available

Memory Function out of power:

Available

Interior diameter of filling

nozzle: 5mm

Lotion

Gear Pump Digital Filler Characteristics:

1. Import single-chip

microcomputer control, high efficiency, low power consumption

2. Automatic counting function,

effectively control filling quantiy

3. LCD display, touch screen is

very easy to operate

4. High filing accuracy

5. Wide Voltage range

6. Working performance is stable

and can be used for long time

7. This can self-suck the

liquid.

8. The pump can stand acid and

alkali

9. Anti-dripping design.

10. Reasonable design, made of

stainless steel, meet GMP requirement

semi automatic lotion liquid filling machine panel function:

Filling time : for adjusting the filling time

Filling time : for adjusting the filling time

Waiting time : waiting time between each filling when the

machine is filling automatically .

Counter : filling counter

Filling speed : adjusting the speed

Fiilling machine controller

: for adjusting the filling range .

When you turn on the machine , push the button "setting" When the filling range

reaches what you want , push the button "setting" once again .The machine will

keep the filling range in memory .

Operation

instruction:

1, turn on the machine ,and put the bottle under the

filling head

2, push the button "setting". When the filling

reaches the range you want , push the button "setting" once again . Then the

machine will keep the filling range in memory .

3, push the button "auto ", and it will work

automatically . Push the button "manual", and it will work manually .

4, the warranty of the machine is 1 year .

The pump is diaphragm pump and is consumable . When

you find the filling turns slow, please change the pump .

Our digital pump filling machine has 1 head, 2

heads,3head,4head and

6heads:

2

nozzles pump digital filler

Three

head gear pump filler

Four

head Lotion Gear Pump Digital Filler

Six

head digital filler

Packaging

& Delivery

1, Packaging Detail: standard export wooden case package or carton.

2, Leading time: 1-3 days

3, Delivery time: depend on ways of shipping

Shipping & payment

1,ways of shipping:

1) Small machine will shipped by express (DHL, EMS, FedEx and so on) or air

2) Big order and big machine shipped by sea (FOB Shenzhen/CIF)

2, payment methods

We

accept LC, TT, West Union , Papal or MoneyGram 1, Packaging Detail: standard export wooden case package or carton.

2, Leading time: 1-3 days

3, Delivery time: depend on ways of shipping

Shipping & payment

1,ways of shipping:

1) Small machine will shipped by express (DHL, EMS, FedEx and so on) or air

2) Big order and big machine shipped by sea (FOB Shenzhen/CIF)

2, payment methods

2016-09-10

mineral water bottle filling machine price small juice filling machine manual filling machine

mineral water filling machine price use for small plant to filling liquid such as mineral water, cooking oils, juice, detergent.

This liquid filling machine using pump and self suck water to bottle through tube,which two nozzles height adjustable.

More detail of this model email to sales@topcnfilling.com

2016-09-08

2016-09-06

2016-09-04

2016-08-10

semi automatic liquid filling machine,liquid filling equipment,bottle filling machinery,used piston filling machines manufacturers

piston filling machines http://www.topcnfilling.com/eproducts/860.html

Pneumatic type of filling machines most commonly applicable for pharmaceutics,daily chemicals, foodstuffs, cosmetics,pesticides and other industrial.

semi automatic liquid filling machine use for filling liquid and paste material, such as mineral water, cooking oils, juice, detergent,sauce, salad, butter&margarine, ketchup, jam, cram, good liquidity of honey, shampoos etc. it is apply for various pacing such as bottle,jar,can,cup,bag, barrels etc.

liquid filling equipment Technology Parameters

I. TSFM series bottle filling machinery are controlled by compressed air, so they are suitable in explosion-resistant or moist environments. II. Because of the pneumatic controls and mechanical positioning, this machine has a high filling accuracy.

III. used piston filling machines filling volume is adjusted by hand wheel, which provides ease of adjustment and allows the operator to read the real-time filling volume on the counter

IV. When you need to stop the machine in an emergency, push used piston filling machines manufacturers the URGENT button.The piston will go back to its initial location and the filling will be stopped immediately

V. piston filling machines has two filling modes for you to choose--Manual and Automatic

VI. Filling precision:0.5%

VII filling speed:15-30 bottles/min

| model | Filling volume | Air consumption | Net weight | Dimension |

| TSFM01-120 | 10-120ml | 30L/min | 22kgs | L55*W49*H122(cm) |

| TSFM01-250 | 25-250ml | 44L/min | 25kgs | L55*W49*H122(cm) |

| TSFM01-500 | 50-500ml | 87L/min | 28kgs | L55*W49*H122(cm) |

| TSFM01-1000 | 100-1000ml | 160L/min | 36kgs | L55*W49*H122(cm) |

| TSFM01-2500 | 250-2500ml | 300L/min | 60kgs | L55*W49*H200(cm) |

Application of liquid filling machine for materials with different voscosity

water---honey sugar---acid cheese---fruit juice---shower gel---gear oil

liquid coffee---ink---eye shadow fluid---tea---shampoo---glue---food/paint

washing hand fluid---cream---milk---liquid soap---butter & margarine

syrup---plant oil---cooking oil---paste---face mask---detergent sauce---salad

butter & margarine---ketchup---jam---honey.

订阅:

博文 (Atom)

Labels

6 heads filling machine

(1)

Abfuellmaschine fuer Fluessigkeit

(1)

aluminum foils

(1)

automatic-filling-machinery

(1)

bag filling machine

(1)

beauty

(1)

bottle

(1)

capper

(1)

capping

(1)

caps

(1)

containers

(1)

customer

(1)

detergent shampoo

(1)

edible oil filling machine

(1)

equipment

(1)

filler

(3)

filler equipment

(1)

filling

(1)

filling capping

(1)

filling capping labeling line

(1)

filling capping labeling packaging lines,TSFM Semi Auto Filling Machine

(1)

filling machine

(2)

filling machine for honey

(1)

filling machine honey bottles

(1)

Filling Machine Line,filling machine

(1)

filling machine operate

(1)

filling machine with different nozzles

(1)

Filling Machines

(1)

finished product

(1)

Gear Pump Digital Filler

(1)

gear pump filling machinery

(1)

hand washing

(1)

honey

(1)

honey bottles

(1)

internet

(1)

lip gross

(1)

lip oil

(1)

liquid

(1)

liquid filling equipment, small packaging machine,self suction filler,filler,vertical filler,semi automatic filler

(1)

liquid filling machine

(1)

Liquid Filling Systems

(1)

liquid package machine

(1)

liquid-filling-machines

(1)

lotion filling machine

(1)

Manual+Bottle+Filling+Machine

(1)

manufacturers

(1)

máquina de llenado

(1)

máquina de llenado miel

(1)

mineral water

(1)

nozzles

(1)

oil

(1)

oil filling machinery

(1)

operation

(1)

packaging machine

(1)

PAFM Automatic Filling Machine

(2)

Perfume

(1)

pharma cosmetic food

(1)

Piston

(1)

rotary

(3)

sauce paste

(1)

screw capping machinery

(1)

seal

(1)

sealing

(1)

semi auto liquid filling machine

(1)

semi automatic

(1)

shampoo

(1)

small filler

(1)

small filling

(1)

solid powder

(1)

stand up bag spout filling machine

(1)

syrup

(1)

syrup.filling machine for liquid

(1)

treatment

(1)

TSFM Semi Auto Filling Machine

(3)

vacuum filling machine

(2)

water purifier

(1)

wave liquid

(1)